that lasts

Steel rope extrusion technology:

Protective sheath for stay cables and

mono strands

jacketing lines for stay cables and strands

Having specialized in extrusion technology for more than six decades, we offer high-end jacketing lines that provide the perfect coating for heavily exposed cables and strands.

If you think of carrier cables for cranes, buildings, or bridges, it will quickly become clear what enormous loads stay cables or mono strands must bear. In addition, they are constantly exposed to external influences such as fog, dust, or salt water. To ensure high durability and strength for 200 years or more, precise processing of these products is essential.

Machine equipment for high demands

Permanent

elastic corrosion protection

100%

longitudinal water tightness

Minimal

internal friction and bending fatigue

Complete traceability and performance control

stay cable production with Rosendahl equipment

Process know-how

with

high customization level

Watch the short video and get a good overview of the main production steps on our extrusion line.

All our steel rope extrusion lines for stay cables and strands will be customized to your individual requirements.

for high durability and strength

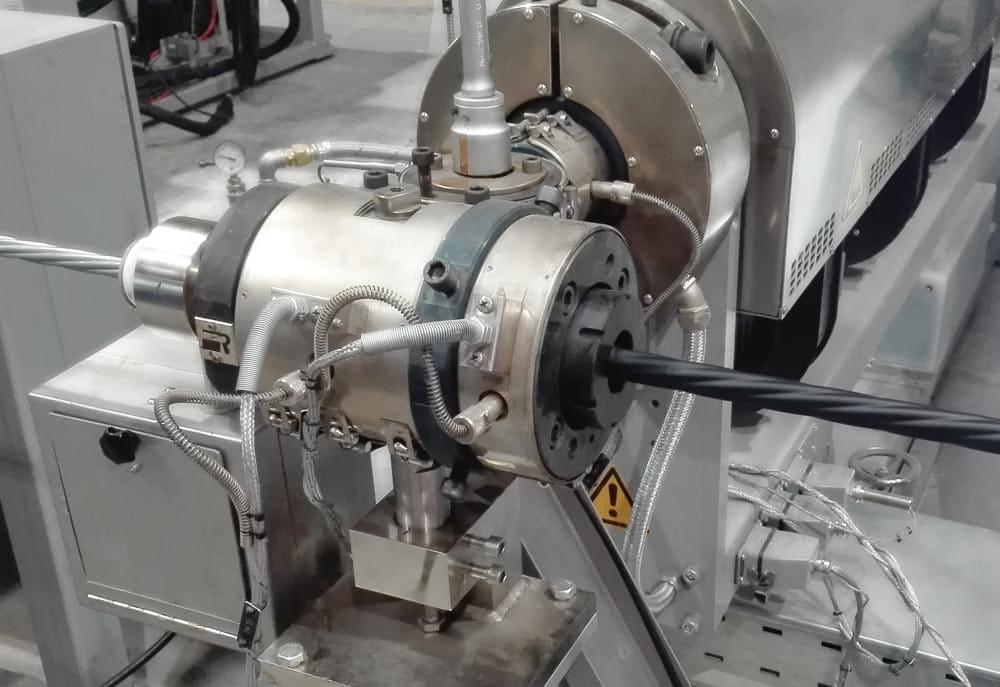

Fully protected stay cables with our RORC 17 preservation station

Our specifically developed RORC 17 station is directly integrated into the line system. It applies permanent elastic corrosion protection all over the rope and its individual wires. For this, the rope bundle is briefly opened and the heated grease or wax is applied at the same time. Immediately afterwards, itis coated with the desired material (PE, PVC, etc.). When the bundle is sealed again, the rope is perfectly jacketed within the required polymer.

quality and performance control

Monitor the grease/wax coating application online

We have recently introduced an online monitoring system for the grease/wax coating application. By using a special sensor, the process is monitored online. This facilitates the quality and performance control during the entire conservation process.

Our smart line control RIO records all the quality parameters and gives you detailed reports on every batch.

technical data

RE-I jacketing line for wire conservation and strand extrusion

-

Conductor steel rope, wire strand

-

Diameter as requested

-

Filling Material wax, grease (for stay cables and mono strands)

-

Extrusion Material PE, PP, PVC, TPU, etc.

covering a wide application range

Product types for the RE-I jacketing line

Stay cables

These products are wax-filled and tightly extruded and may therefore deviate from circular the shape at the outer periphery.

Applications:

cable-stayed bridges, towers (e.g., for antennas), wind power stations, chimneys, etc.

Mono strands

Primarily used in civil engineering in pre-stressed concrete structures. They are grease-filled and semi-tube extruded in a round shape.

Applications:

silos, tanks, high-rise buildings, foundation columns, building slabs, bridge and road structures, etc.

Plastic-coated / filled wire ropes

All the spaces between the strands and voids are filled with a plastic matrix. The plastic encloses the rope up to the surface.

Applications:

offshore ropes, crane and special mining ropes, lifting ropes, guardrails, catenary systems, barrier ropes, etc.

Tailor-made in Europe

We develop customized solutions for your specific needs

contact

get in

touch

with us

Tailor-made manufacturing solutions are our specialty. If you need any additional information on the equipment we provide, please feel free to contact us. We will be happy to help you find a manufacturing solution that fits your needs perfectly.