low voltage.

high quality.

Insulation. Jacketing. Stranding. Customized production lines for low-voltage power cable manufacturing

tailor-made machines for the low-voltage power cable segment

The range of low-voltage cables includes many different cable types for countless applications. That also means that the demands on production lines are often customized. Regardless of which materials, structures, or forms are required for your products, we’ve got you covered.

Flexible machinery for multiple fields of application

Low-voltage power cables are needed in many fields. To cover as many of today’s market needs as possible, we configure our low-voltage cable equipment exactly according to your needs.

- Building wires & house wiring products

- Signal and control cables

- Cables for the automotive, shipboard, and aerospace industries

- Solar cables

- Submersible cables – winding wires or oil pump cables

- Medical cables

- Aerial bundled cables (ABC or SIP)

- Elevator cables

- Underground cables

- Fire safety cables

- Locomotive wires

- Nuclear power cables

- And many more

tailor-made in europe

Decades of experience in all segments of wire and cable insulation projects

An extensive portfolio of successfully installed systems worldwide confirms our success

proven technology for excellent results

We put your material to the test

Depending on the type of cable, various extrusion materials are used for cable production. We maintain close links with leading granulate suppliers and have been testing and optimizing new material grades on Rosendahl equipment for many years. Therefore, we can offer proven machinery and broad process know-how for a vast number of grades used in the wire and cable business.

- Standard grades: PVC, HFFR, PE, …

- Special grades: TPU, FEP, PEEK, …

- Cross-linkable grades XLPE: Sioplas, co-polymer, dry & liquid silane, …

Research and development at Rosendahl Nextrom

We are permanently researching and testing new material components.

energy-efficient silicone extrusion

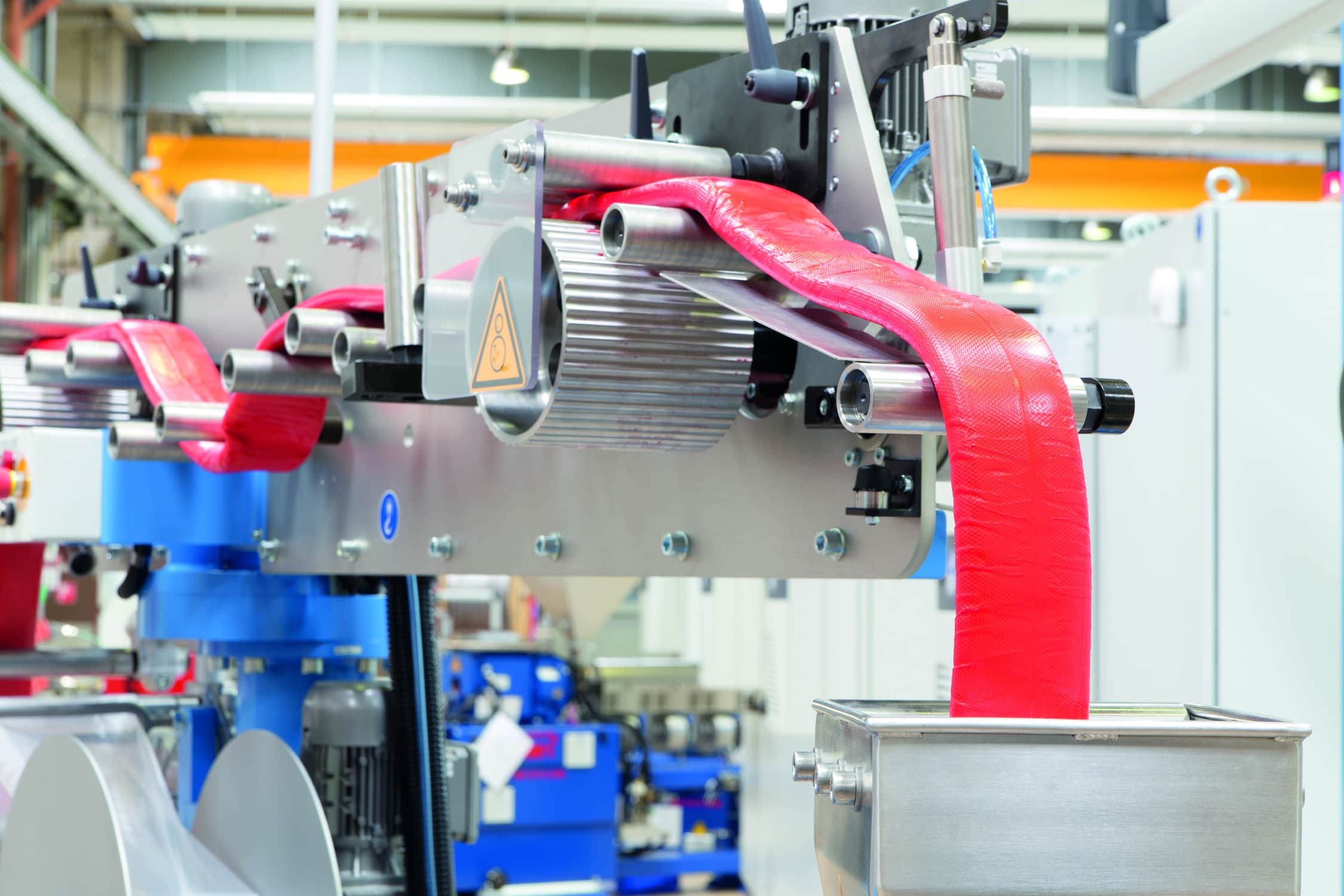

Infrared curing for silicone

To make silicon cables resistant to high temperatures, they need to be cross-linked. Rosendahl machines rely on infrared curing. Compared to other cross-linking methods, infrared curing is more efficient and flexible, with minimum scrap rates and easily controllable parameters. It is even up to 15% faster than hot air systems and consumes around 30% less power during production.

are you investing in renewable energy?

Solutions for the production of solar cables

Thinner walls on solar cables, higher production speeds, lower investment costs, shorter line lengths, and more. We constantly adapt our manufacturing processes to meet the current and future market requirements of the solar industry.

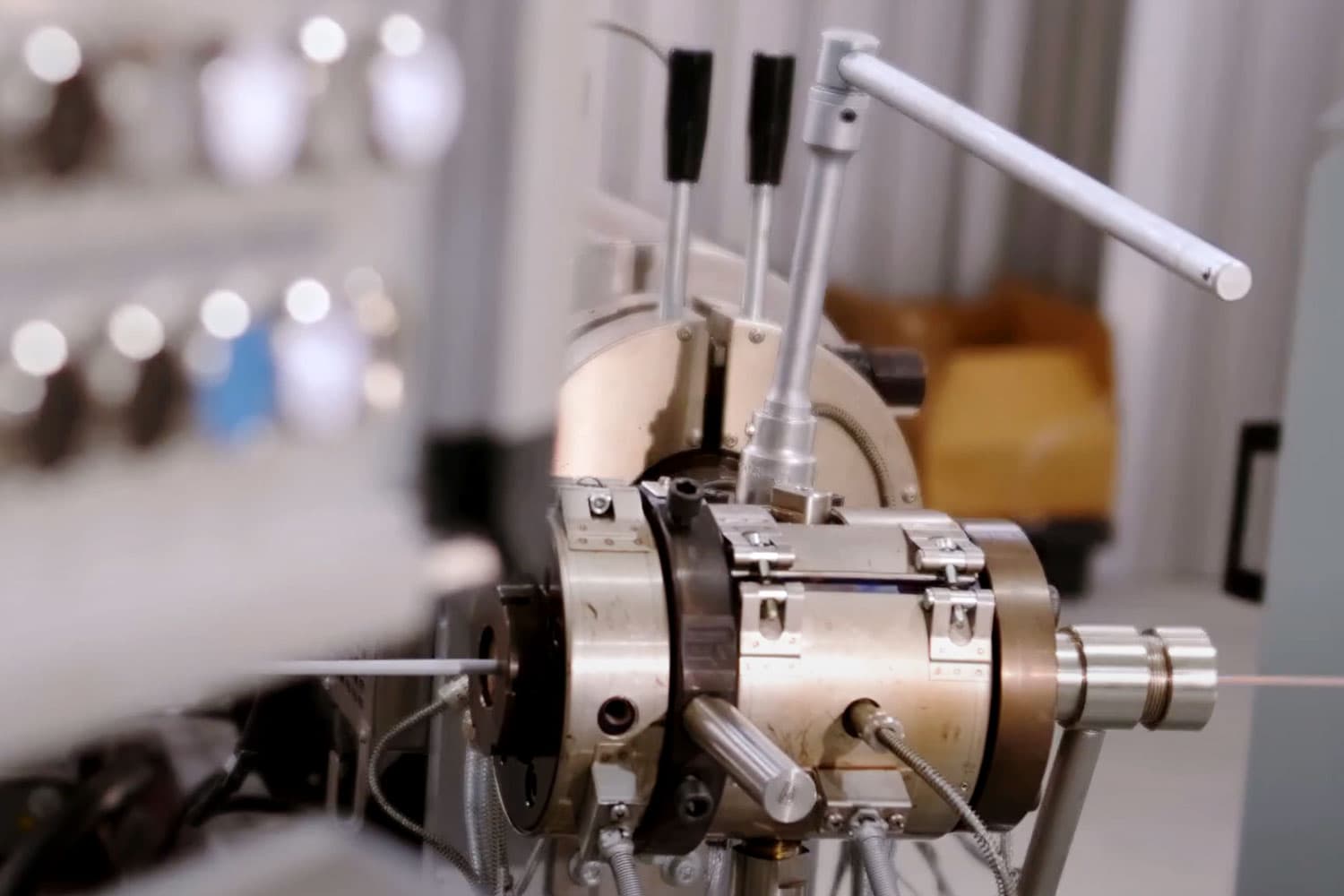

THHN/THWN/TWN Wire Extrusion

High flexibility for different cable types

We have developed a variant of our RN-A production line especially for THHN/THWN/TWN products. It is designed to process a wide product range on the same line: classic building wires, control cables, or high-end cross-linkable / halogen-free and flame-retardant insulated conductors.

The customized line delivers high output and quality and is configured for fully continuous production with speeds of up to 1,200 m/min, even for printing.

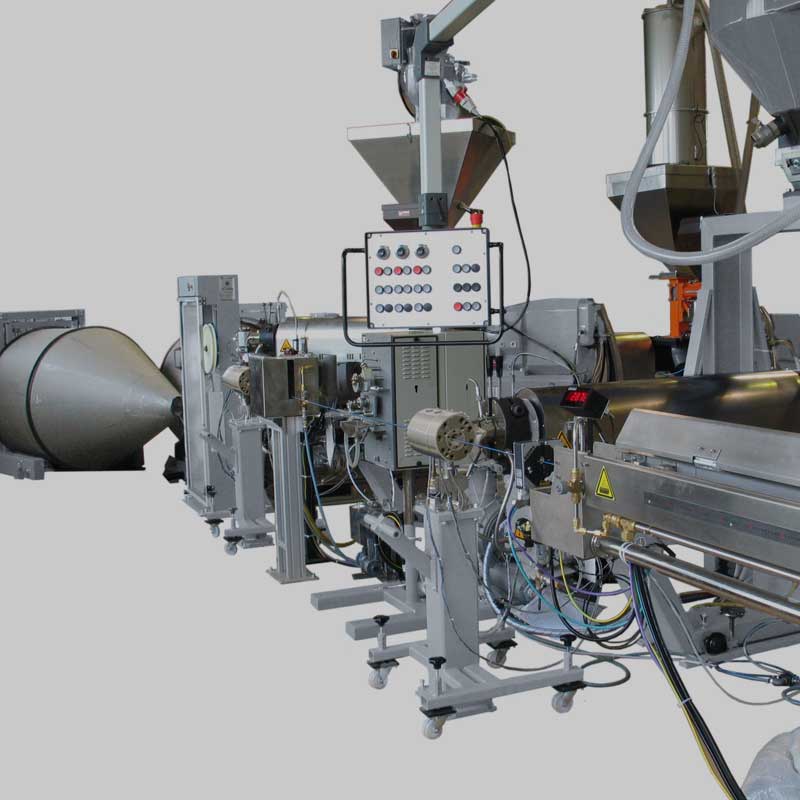

overview

Rosendahl machinery for low-voltage cable production.

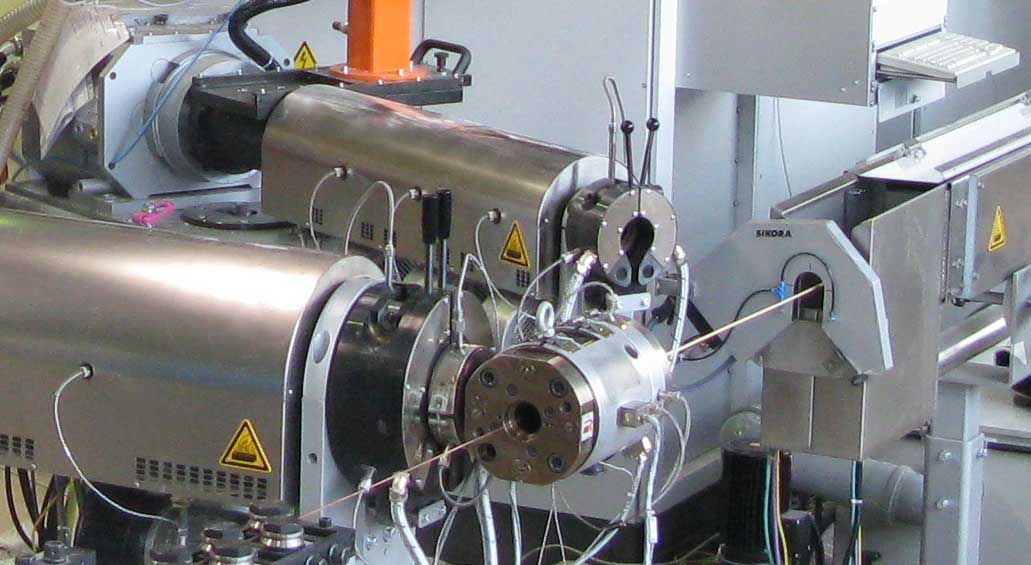

RN-A

insulation line

for a wide range of low-voltage power cable products

RN-M

jacketing line

for cables with an outer diameter of up to 200 mm

RN-Z

extrusion line

for silicone materials with infrared curing

RN-K

combined SZ stranding, filling, and jacketing line

for continuous production

Tailor-made in Europe

All key components such as extruders, crossheads, and capstans are designed and manufactured at our facility in Austria.

contact

get in

touch

with us

Here for you

Are you looking for a high-end solution for a wide range of low-voltage power cable products? Whether your major focus is on the highest productivity possible, a huge product range, space-saving design or unique product quality, Rosendahl is the right contact. Our continuous product development and long years of experience make us a first-class partner for any standard or special need in this segment.