our smart

solutions

Control, monitor, and analyze your production process with our powerful line control

Rosendahl integrated operation system

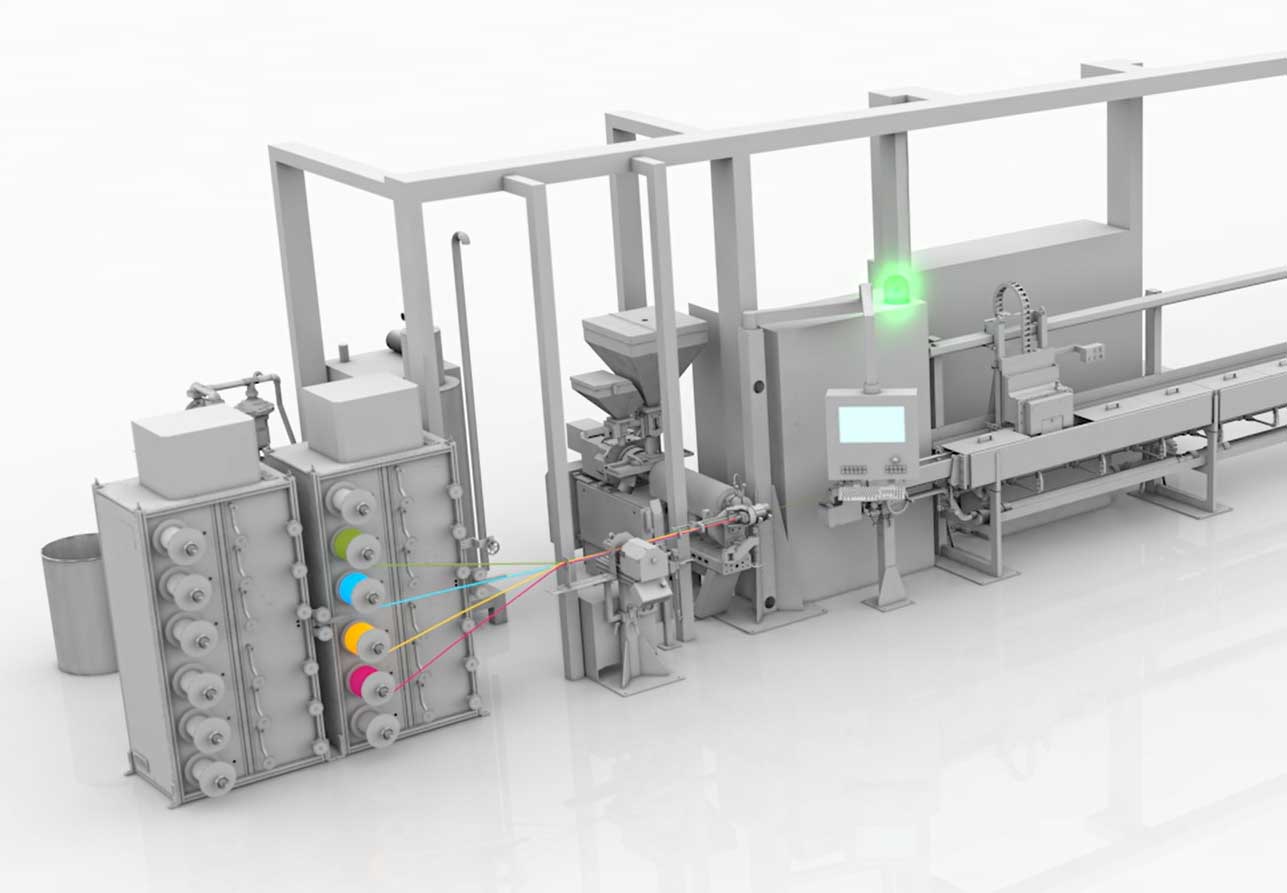

Meet RIO, our powerful line control for Rosendahl setups

With its modular design, it is a perfect fit for all applications. You can choose from a large variety of tools and add-ons, and build your own customized environment, perfectly tailored to your needs. Keeping track of your production process has never been easier.

- Vital reporting and analyzing instrument

- Hardware-independent

- Unlimited connectivity and resources

- Integration of 3rd party software tools

- Suitable for complex applications

countless benefits for your production process

RIO translates data

into possibilities

Reduce your scrap rate significantly

Retrace each step of your production process

Access quality and error reports

Get real-time reports and interpret historical data

Track the batch information of your raw material

Prepare for maintenance and upgrades in time

Compare the OEE between lines, products, and shifts

Use proven parameters for your next job

safe. efficient. profitable.

RIO’s smart and flexible setup will level up your production

Smart Factory Office

Get your reports and statistics to your office desktop with this smart software bundle. Our ready-to-use reports and add-ons for Microsoft Office® Excel® and Word® are optimized for data acquisition, analysis, and reporting. That is especially useful for you if you have one or more Rosendahl lines at one production site.

Smart Factory Cloud

Access your data anywhere, anytime, and on any device. With RIO’s Smart Factory Cloud, you get convenient access to data from different lines from different facilities. You decide if you want to store all the data or just parts of it in the cloud. All the data are encrypted for maximum data security.

Consumption Measurement

Make your production process as energy-efficient as possible. Our additional sensors and gauges will measure the consumption of electric power, compressed air, water, and plastic material during production.

Extruder Screw Identification Marking

Equip your extruder screws with RFID chips. That is the smart way to keep track of your screws’ operating data. It will avoid the risk of operating errors on your production line and help ensure you get the best-quality product.

Integration in ERP/MES-Systems

Connect the RIO line control to your existing business software solutions. That way orders can be transferred directly from ERP / MES systems to the RIO line control system. The information and current status of the individual orders are then reported back.

user-friendly data analysis and reporting

Smart Factory becomes reality

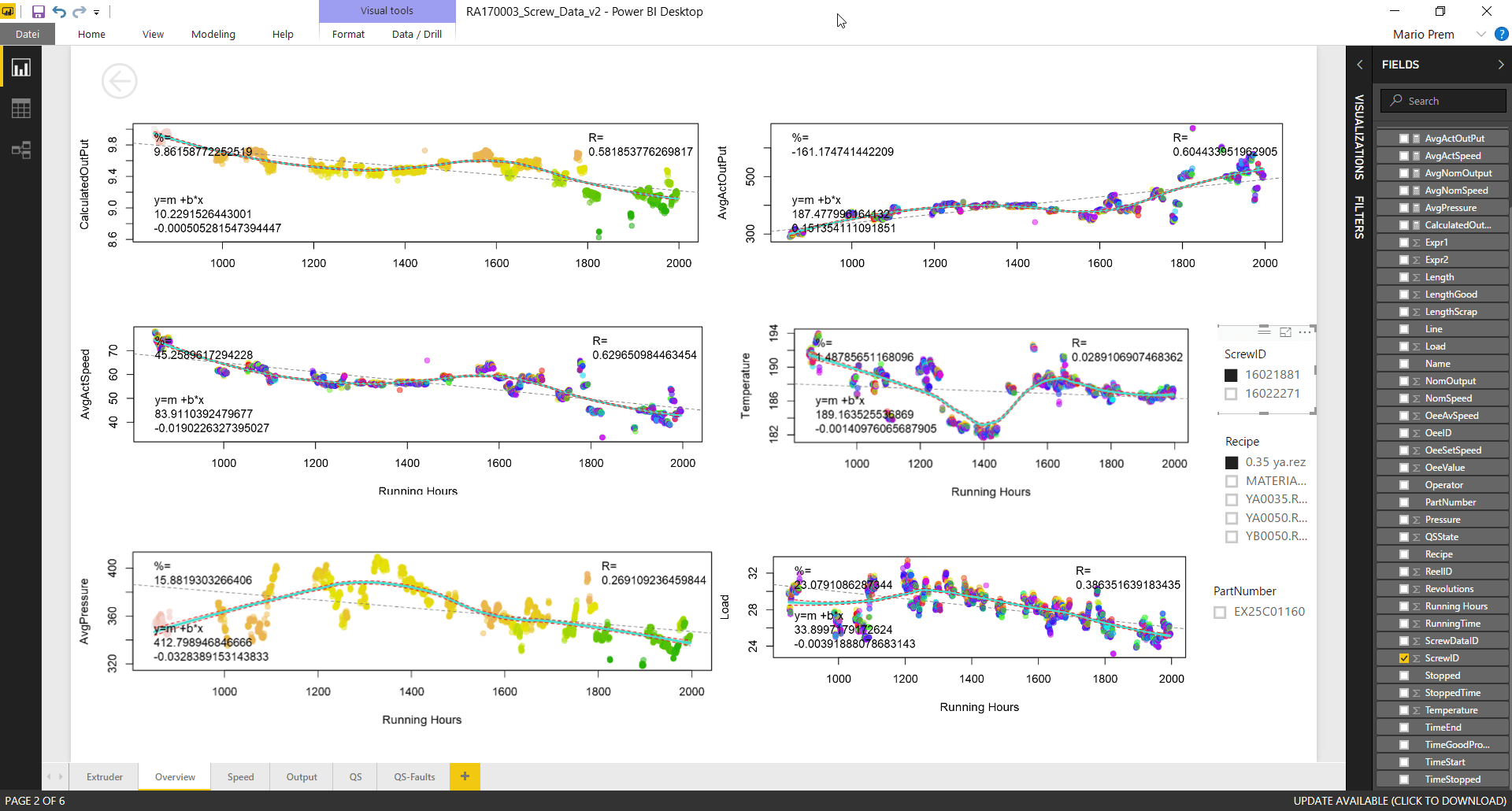

Our smart line control system RIO makes it easy for you to keep track of all the processes and parameters you need to fully exploit the potential of your production line. With the help of machine-learning algorithms and intelligent data evaluation, you will always be ahead of your production process.

- Get a complete overview of your production processes in real time

- Turn your industrial data into powerful insights

- Use the full potential of your entire production process

never stop optimizing

Your production plant generates data 24/7 – even when it is not running. Don’t let this valuable data go to waste.

There is always potential for optimization in your production process. You may want to increase your production speed while maintaining the same quality level or simply reduce your energy consumption. RIO helps you detect room for improvement. It provides all the data you need to analyze, compare, and optimize your production.

user-friendly design

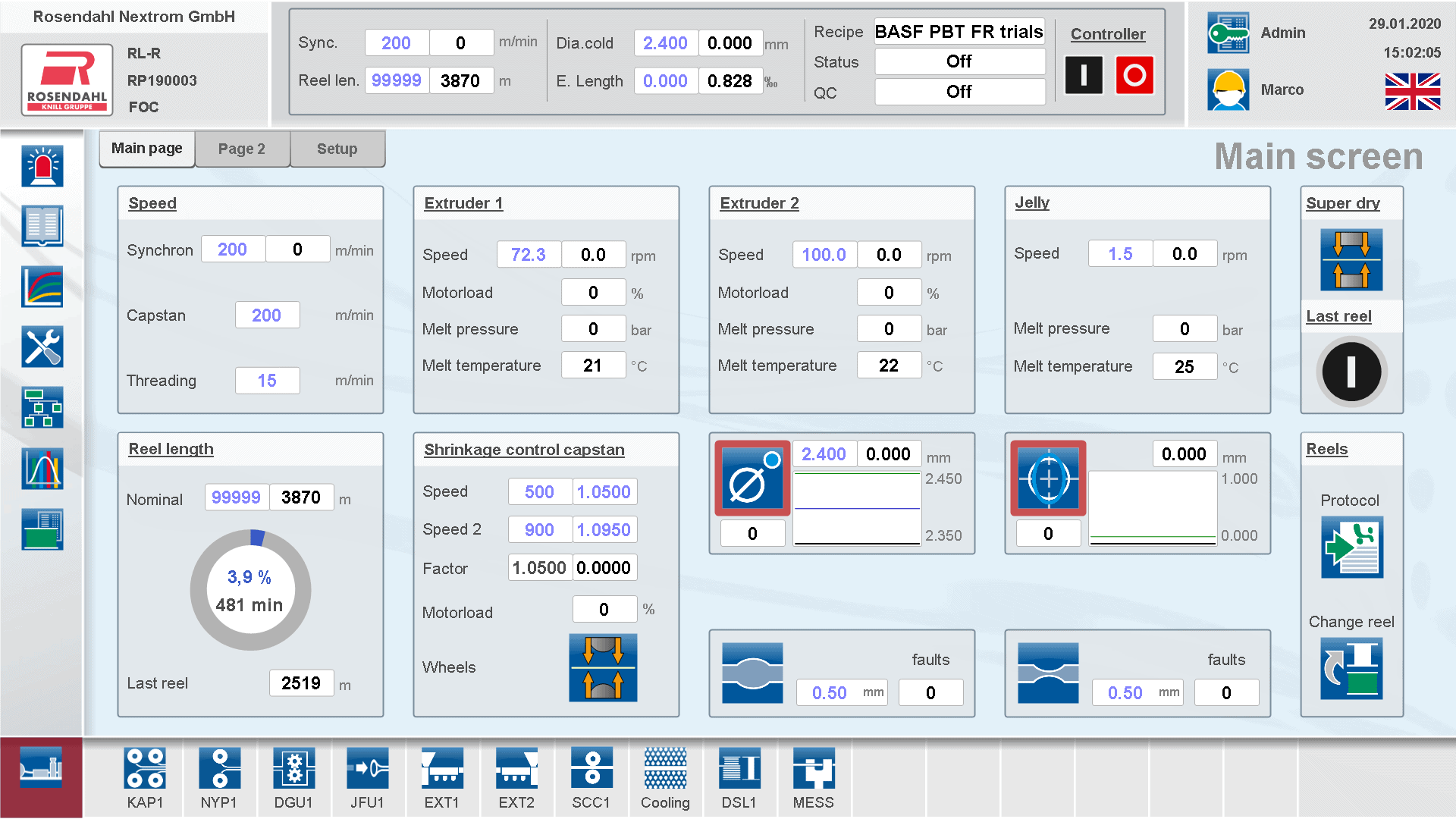

A user interface exactly tailored to your needs

Don’t waste your time with information you don’t need. You’re an operator? Then the key parameters of your running production will be the data you’re looking for. You are a manager? Then you’re probably interested in quality reports and analyzing tools.

- Get all relevant data at a single glance

- Define specific roles and authorizations

- Save individual language settings for your profile

- Customized dashboard with intuitive user interface

RIO optional modules

QMS monitors the current product parameters measured, such as diameter, eccentricity, and dielectric strength. Values and tolerances can be defined freely for alarm reporting and entry in the reel certificate, product assessment, and line shutdown.

That allows for a clear monitoring of the actual process by standardized indexes. Over the various batch sizes, the SPC module calculates the mean value, the standard deviation, minimum and maximum values, the process capability indexes as well as the machine capability indexes.

Electrical energy consumption is continuously measured and recorded. That enables the evaluation of the energy costs by ready-to-use reports like energy consumption over time, energy costs per km of cable, etc.

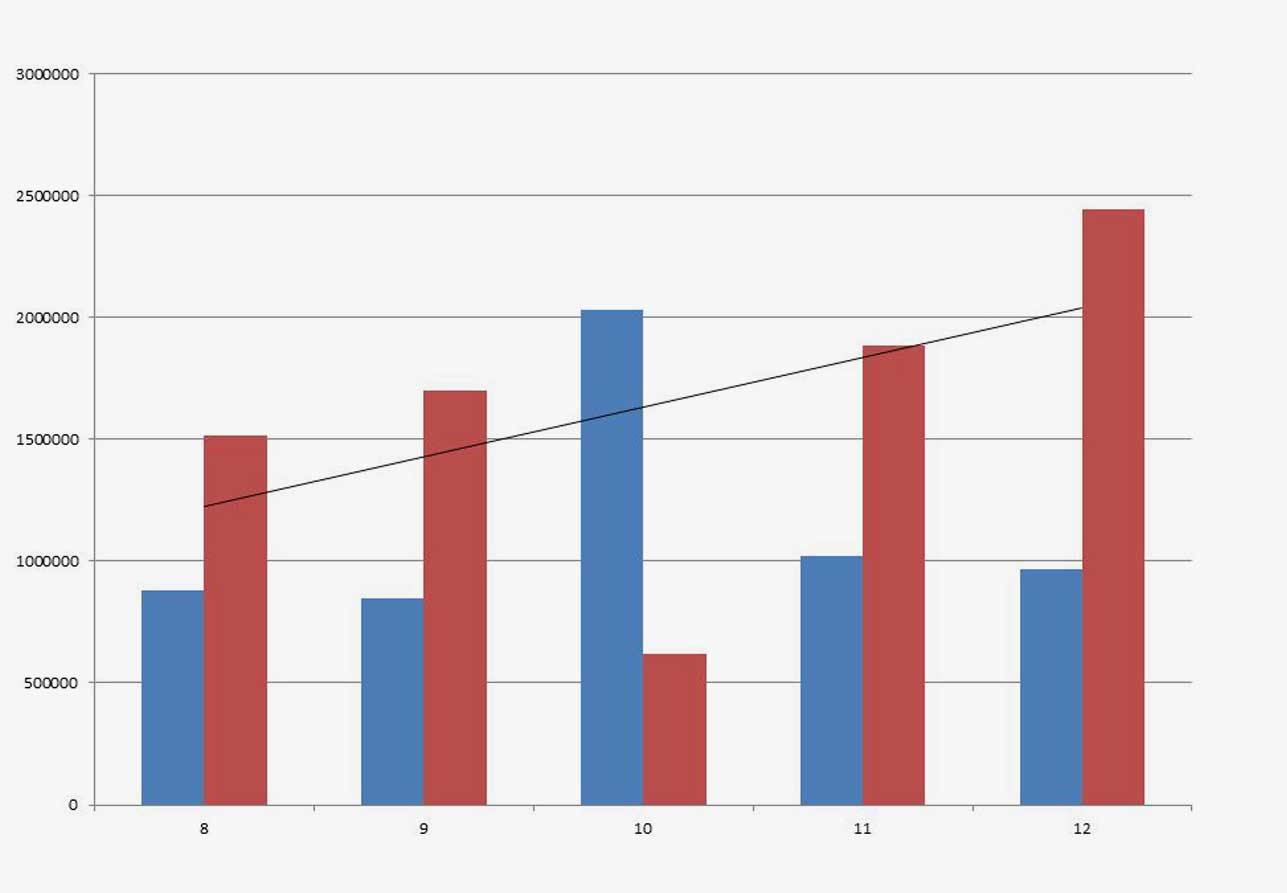

The Overall Equipment Effectiveness (OEE) is a key indicator which describes the effectiveness of the entire production process. The RIO SIM module for reports and evaluations has been systematically customized for use in continuous improvement. Data is acquired in production, measured and in particular results are visualized.

Integration of up to four cameras via PoE (Power over Ethernet).

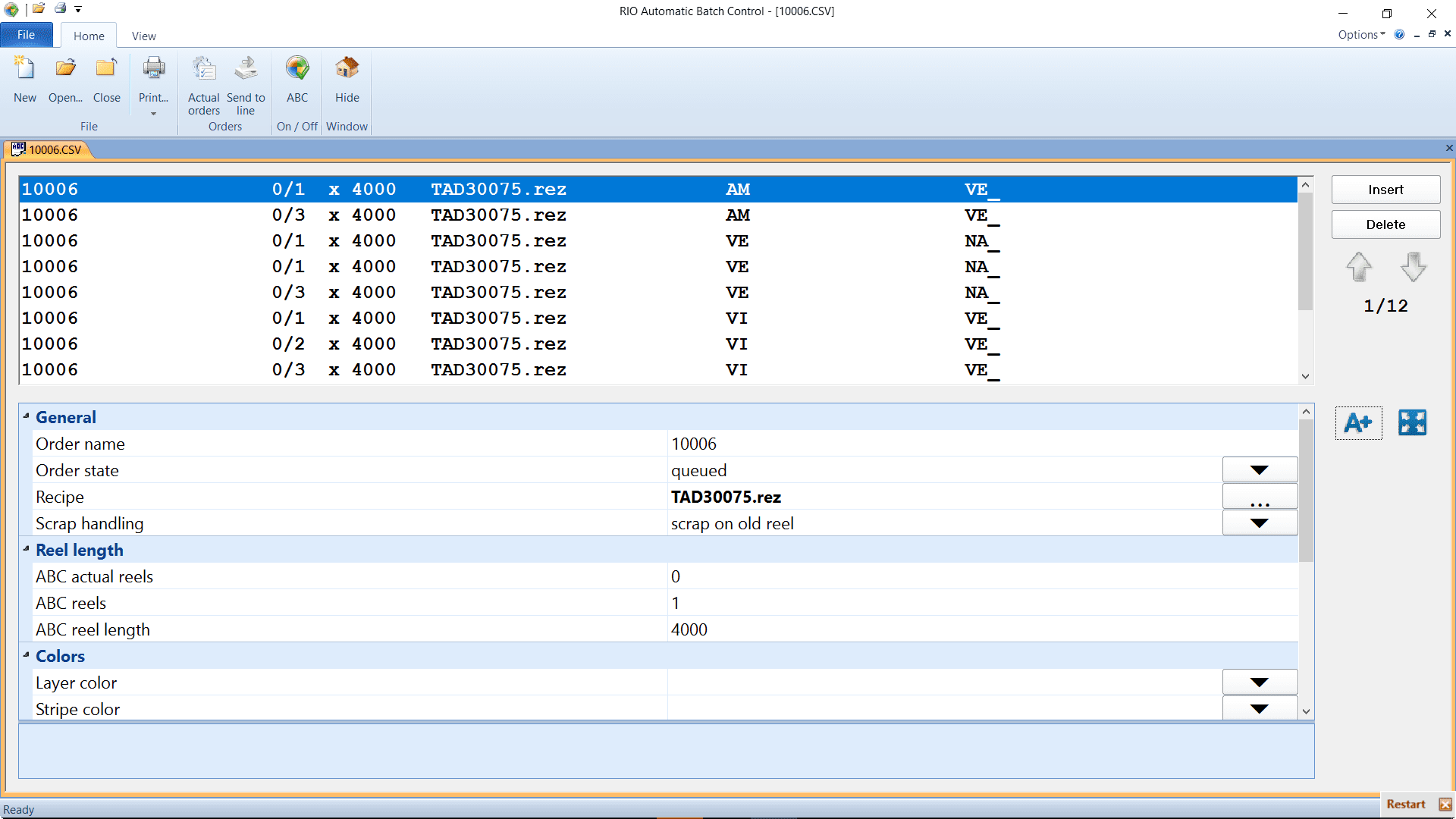

By means of an editor, it is possible to specify and process the planned batch sizes on the line. That allows for the definition of essential parameters, such as order number, product type (recipe), number of coils required, batch size lengths, color, and marking as well as transition to the next batch size block. The feeding of production batch sizes can be deposited in a data file with batch size parameters by a primary computer. After the line startup, the tasks, such as changing recipes, specifying length pre-selections, inserting scrap lengths as a function of recipe parameters, blocking, color change, freezing, and enabling of process controllers as well as machine shutdowns are carried out by the line control system.

Customized as well as standardized interfaces (OPC-UA) for integration into existing MES/ERP systems.

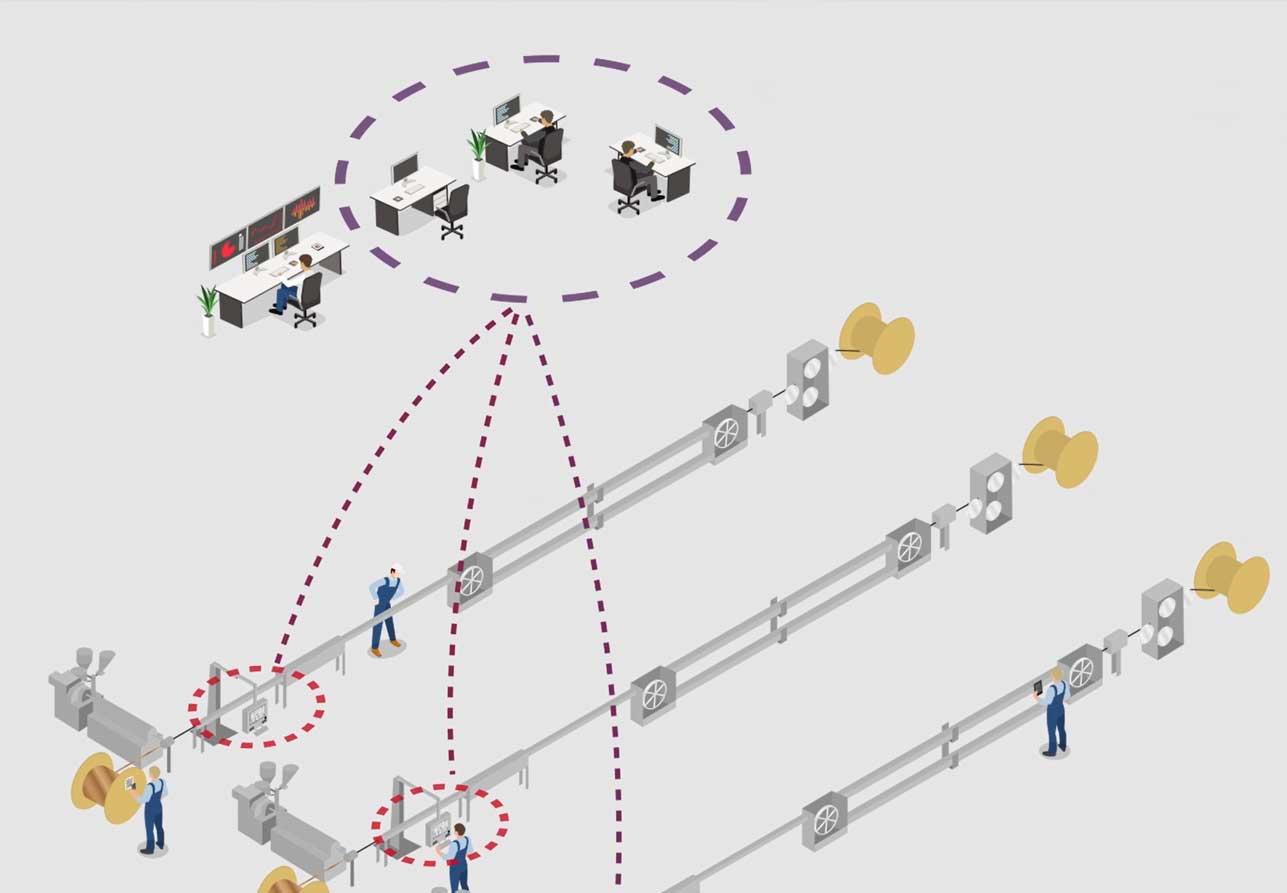

With this concept, it is possible to operate every connected line in the plant by means of RIO. All combinations ranging from a parallel operation of a line from several operating stations to a crosswise operation are possible.

This kit enables you to modify the line control system. You can configure free analogue and digital in-/outputs, HMI-tags, actions, alarm messages, etc. simply by using “drag & drop”. Furthermore, you can customize existing process parameter reports and reel reports.

RIO standard modules

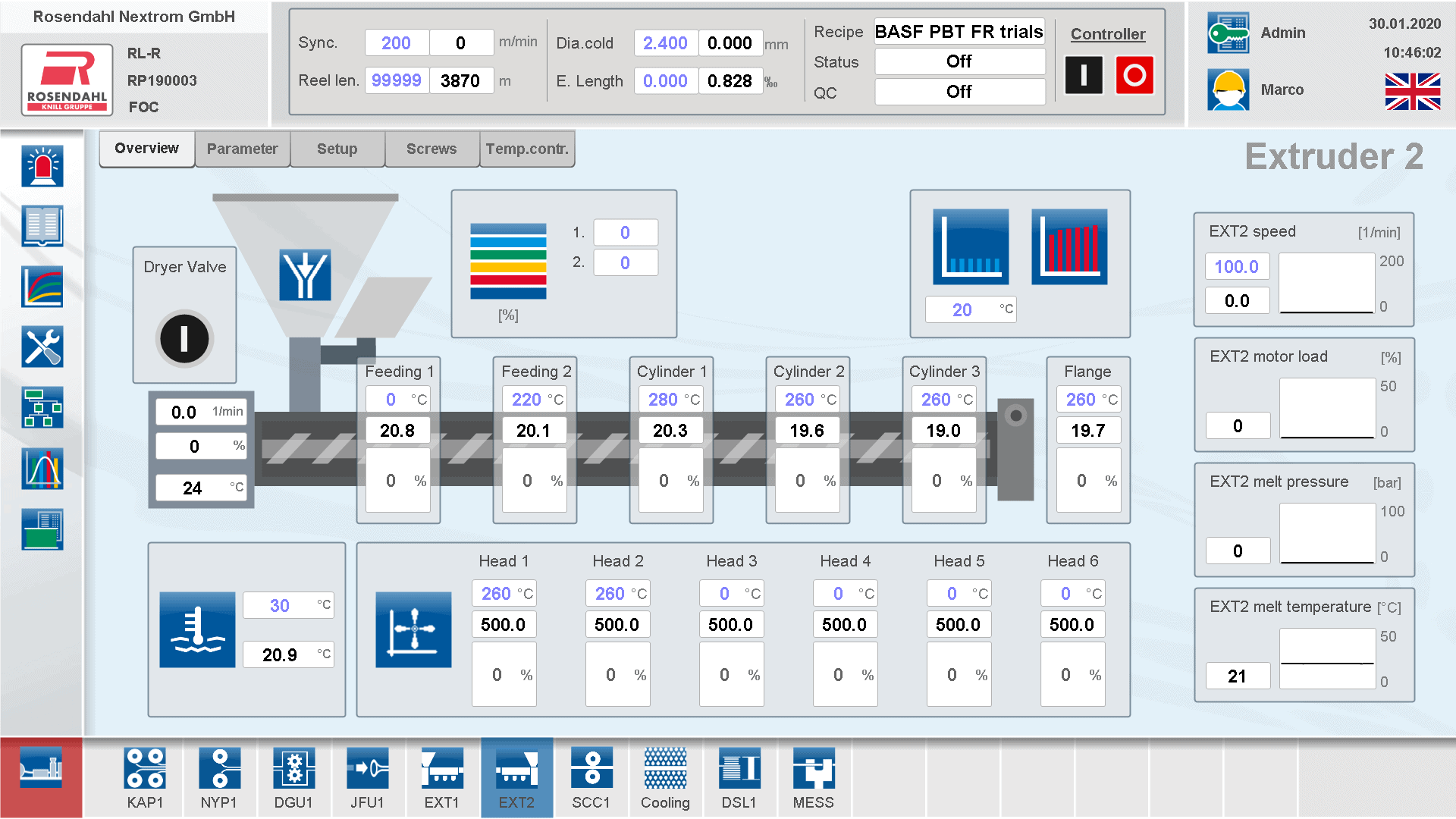

The graphic user interface displays general diagrams and images with the required parameters. All the pages have a help system, allowing for operation without prior special knowledge. With the option of opening more than one window, it is possible to work on more than one module at the same time.

Machine-overlapping control functions in clearly arranged display and in animated block diagrams.

This is a convenient system to notify the operator of any troubles, historical alarm management, fieldbus monitor, etc.

Operation by touch screen and remote station. Multi-language operation.

This system offers all the functions to generate, modify, and manage recipes. Proven parameters can be uploaded and reused for the next job.

This system offers a convenient solution for the generation of labels, reel protocols, shift reports, etc.

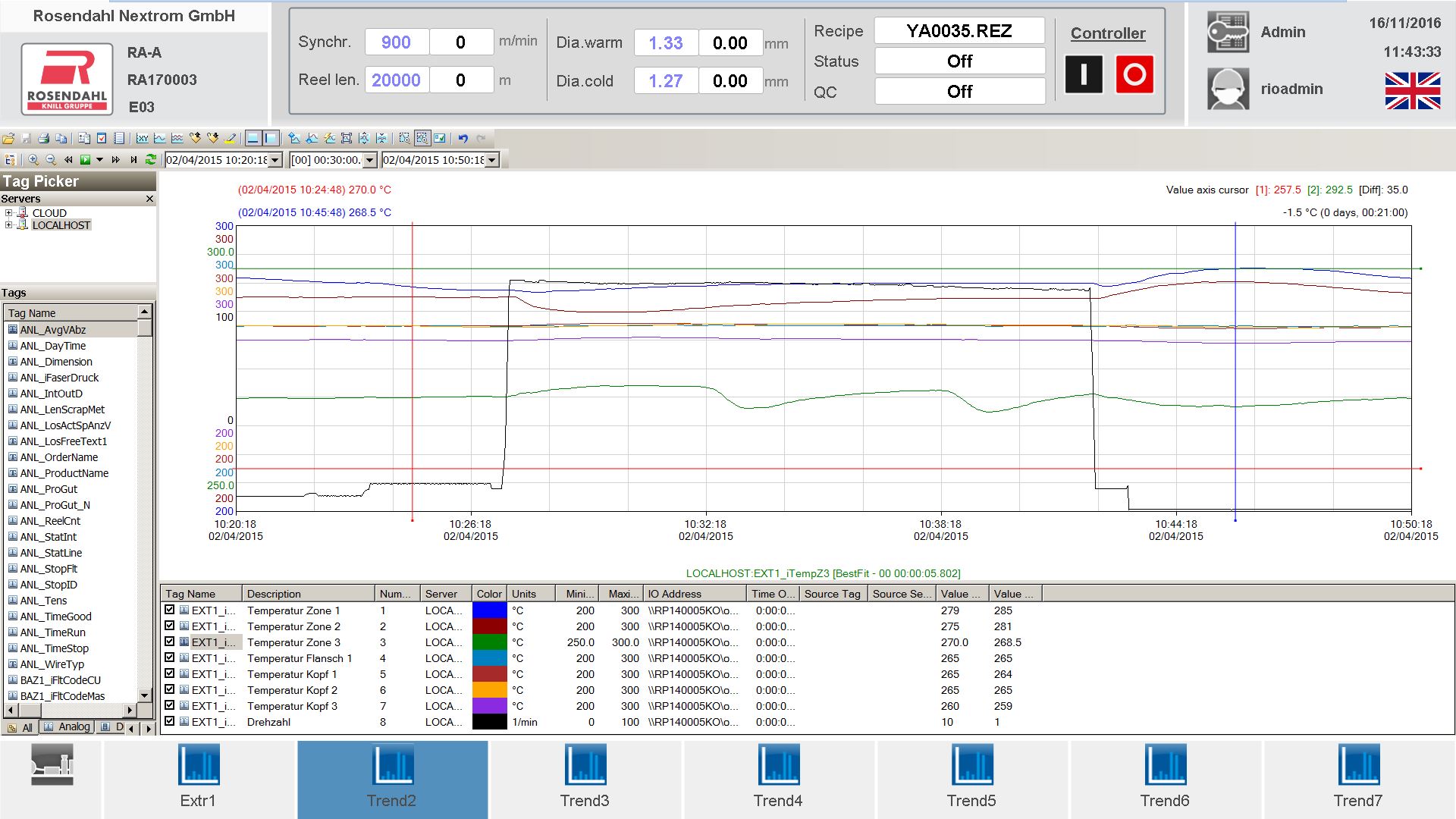

Trend means real-time and historical processes from industrial SQL data in a graphic view. Text and variables from one or more servers can be collected and displayed, depending on sequence, color, numbers, and adjustment. Trend can display the X-axis and Y-axis cursor with difference values, public and private notes, alarm values, and alarm conditions for accurate analysis.

With tools like VNC, Teamviewer, or Remote Desktop, you have access to the line control system from anywhere.

Easily print your own labels, reel protocols, print screens, and process parameters.

Remote operation and remote servicing can be provided by modem or Internet. All the operating stations can be equipped with a manager driver and/or client driver to support each other.

- Standard interface

- Independent, modular utilization of stand-alone units

- Reduced cabling

- Customer Machine Integration

contact

get in

touch

with us

You want to know more about RIO line integration or how it can be implemented in your existing production process? Maybe you would like to see a live demo? Contact us for further information. We’re happy to answer all your questions and show you what RIO can do for you.